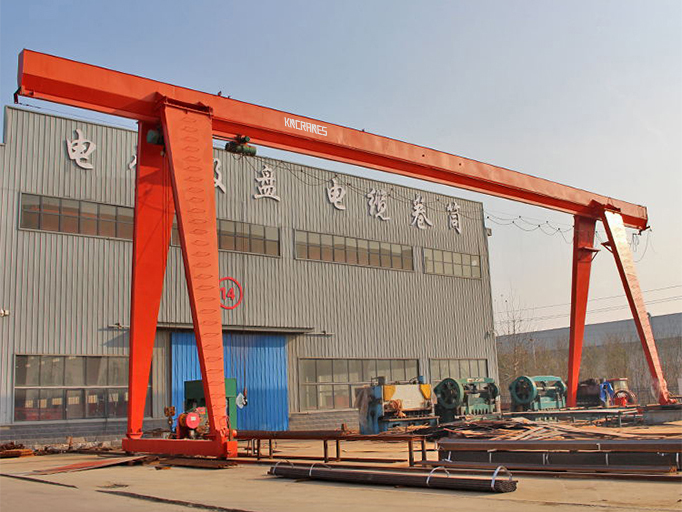

An overhead crane, also known as the bridge crane, is then type of crane where the hook-&-line mechanism runs along the horizontal beam that runs along two widely separated rails. Often it is in a long factory building & runs along rails along the building’s two long walls. It is similar to a gantry crane. Overhead cranes characteristically consist of either single-beam or double-beam construction. All such can be built by using typical steel beams or complex box girder types.

When it comes to optimizing your material handling processes, investing in a Single Girder Overhead Crane is a wise choice. These powerful pieces of equipment can significantly enhance your operational efficiency. However, it’s crucial to select the right overhead crane company to ensure that you get a reliable and high-quality product.

Double girder bridges are more typical when needing heavier capacity systems from 10 tons and above. The box girder configuration results in a system that has a lower deadweight but stronger overall system integrity. This system includes a hoist to lift items, a bridge that spans the area covered by the crane, and a trolley to move along the bridge.

The most common use of overhead cranes is in the modern steel industry. At every step of the manufacturing procedure, until it leaves the factory as a finished product, steel is handled by the overhead crane. Raw materials are dispensed into the furnace by crane, hot steel is stored for cooling by the overhead crane, the finished coils are lifted & loaded onto trucks & trains by the overhead crane, & the fabricator or stamper uses the overhead crane to handle the steel in the factory. The automobile industry uses modern overhead cranes for handling of the raw materials. Smaller workstation cranes handle lighter loads in the work area, like CNC mill or saw.

Use of Overhead Crane

Almost all the paper mills use bridge cranes for regular conservation requiring the removal of heavy press rolls & other equipment. The overhead cranes are used for the initial construction of paper machines as they enable the installation of heavy cast iron paper drying drums & other heavy equipment, some weighing as much as 70 tons. Single girder overhead cranes are relatively simple to install, reducing downtime in your operations. Furthermore, their design makes them easier to maintain, resulting in fewer maintenance costs and less operational disruption.

Conclusion

Investing in a single girder overhead crane can significantly improve your material handling efficiency, but choosing the right Overhead Crane Company is equally crucial. Take your time to research, consider your specific needs, and prioritize quality and safety. A reputable company will work with you to customize a crane that suits your requirements and adheres to industry standards. Remember that the initial investment in a quality single girder overhead crane will pay off in terms of improved productivity and cost savings over time. Make the right choice today and reap the benefits of efficient material handling in your business.